Predictive Fleet Maintenance with data-driven insights predicts equipment or vehicle failure. Fleet management is crucial to maintain cost efficiency, operations, and user safety. Leveraging fleet software helps in gaining vehicle data, analyzing it in a timely manner, and maximizing operational outpoint. As fleet software puts light on new avenues that require optimization, data nonetheless plays an essential role in providing timely maintenance, safety and performance alerts among others.

Herein, connected vehicle data, telematics, and embedded telematics help in collecting fleet data using different sources to get accurate user data and take proactive steps to maintain fleet efficiency.

This article discusses in detail what is predictive vehicle maintenance and how it helps in heightening fleet performance.

What’s the Difference: Preventive vs Predictive vs Proactive Maintenance

The primary difference between preventive, predictive, and proactive maintenance is based on the schedules. While preventive maintenance does not use current data, predictive and proactive maintenance employ the existing state of the fleet and remedies to increase fleet management.

Knowing the difference between preventive, predictive, and proactive fleet maintenance is imperative to develop an accurate maintenance plan.

| Preventive Maintenance | Proactive Maintenance | Predictive Maintenance |

| Uses human intervention through electronic and manual tools through regular scheduling | Uses CMMS (computerized maintenance management system) | Uses automated systems |

| Helps to prevent futuristic breakdowns | Helps reduce overall repair cost | Helps reduce unexpected machine maintenance |

| Data throws light on vehicle performance and areas of damage | Data throws light on latest trends and performance metrics | Data throws light on areas that need maintenance using predictive analysis |

| Does not use existing vehicle condition | Uses existing vehicle condition | Uses existing vehicle condition |

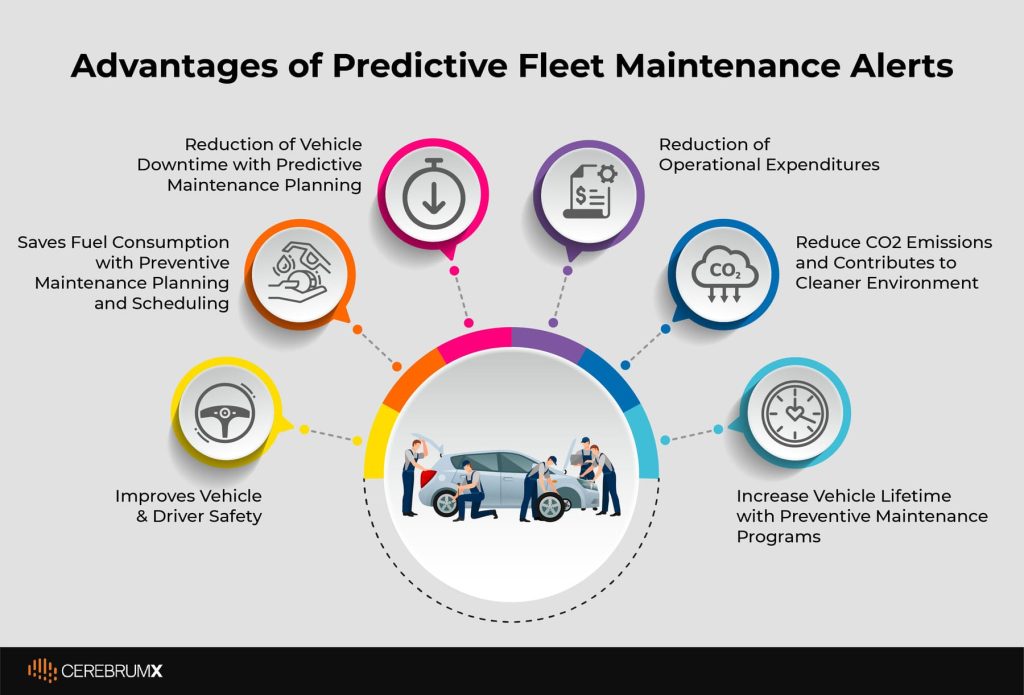

Advantages of Predictive Fleet Maintenance Alerts

1. Improves Vehicle & Driver Safety

It primarily helps in reducing problems arising due to manual errors. It highlights pain points that may go unnoticed by the human eye. Furthermore, an increase in irresponsible driving and misconduct of drivers makes it difficult to understand the case.

- Analyze tire pressure

- Clear bugs, replace wiper and prevent freeze

- Assess vehicle airbags

2. Saves Fuel Consumption with Preventive Maintenance Planning and Scheduling

Scheduling timely preventative Fleet maintenance planning ensures there are reduced CO2 emissions and avoids irregular consumption of fuel

- Avoids increased fuel consumption

- Prevents CO2 emissions

- Saves fuel costs

3. Reduction of Vehicle Downtime with Predictive Maintenance Planning

It helps understand the vehicle’s loopholes that may lead to breakdowns. Herein, planning out regular predictive Fleet maintenance aids in reducing vehicle downtime.

- Reduces maintenance cost

- Reduces downtime

- Maximizes fleet availability

- Prevents vehicle breakdowns

4. Reduction of operational expenditures

It renders the user to understand the potential issues that may arise in the vehicle. In addition, it assists in planning resource allocation and managing expenditures within budget.

- Prevents additional costs

- Enables allocation of funds

- Allows forecasting maintenance

- Decreases repair costs

5. Reduce CO2 Emissions and Contributes to Cleaner Environment

Predictive Fleet maintenance ensures timely checks on the vehicle to reduce overall CO2 emissions. Additionally, a well-maintained vehicle provides optimal performance and betters fuel by detecting minor or significant issues related to the car in advance.

- Foresee and fix issues

- Reduces carbon footprint

- Detects major and minor issues

6. Increase Vehicle Lifetime with Preventive Fleet Maintenance Programs

Intelligent vehicle monitoring ensures extending the fleet’s shelf life. It helps to monitor and fix any problems before the damage turns severe. In addition, it prevents overall downtime and the need for sudden repairs.

- Reduces vehicle wear and tear

- Increases vehicle shelf life

- Fix vehicle assets and repair issues

Features to Consider When Choosing a Predictive Fleet Maintenance Software

Predictive Fleet Maintenance software uses automotive tools to perform regular fleet maintenance, preventing manual errors.

1. Preventive Maintenance Schedules and Alerts

The software sends periodic notifications and alerts to perform maintenance activities. It uses pre-set monitoring metrics and service records to send automated maintenance alerts and schedules.

2. Risk identification: Easily identify vehicle needs & maintenance risks

Predictive maintenance software detects critical situations and highlights areas that require immediate attention. It enables the capture of a range of performance data, analyzing driver behaviour and checking the external surroundings to accurately store vehicle metrics and other variables, assisting in identifying risks.

3. Data Management: Collection and Organizing Your Data

The software helps to collect relevant data, define metrics and measure the overall impact on vehicle maintenance. Its intuitive dashboard organizes data through reports, visuals, and summaries to access and synchronize the information. It helps in building better strategies and developing decisions.

Conclusion

CerebrumX’s predictive and preventive maintenance system utilizes AI and user data to improve fleet efficiency, reduce costly breakdowns and improve facilities using advanced data analytics tools. Better your fleet maintenance by connecting with CerebrumX. Get Started with us today.